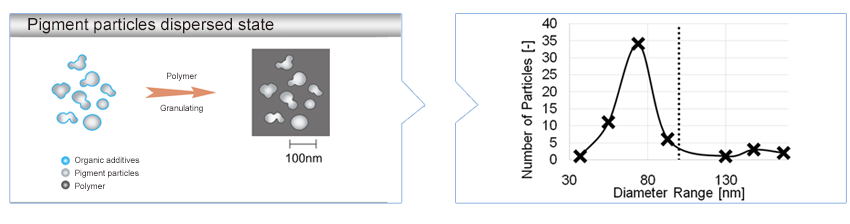

Nano grade particles are round in nature. How to make each particle remain and exist independently and still maintain the nano state when using the nano particles applied to final application environment is a big technology challenge in the industry today.

The core of Eisvogel nanotechnology is that it ensures each pigment particle is coated and isolated in its original appearance and size, and prohibiting the agglomeration in the process of product realization. The original shape and size of nano particles is well protected in the chosen polymer.

As illustrated in the figure below, the surface of nano-grade primary pigment particles are coated to reduce the acting force between particles which are agglomerated, in order to protect the primary particle size and shape.

Pigment shapes shown in the following pictures (the appearance shape will be different by pigment content) can be powder form or granular form. The coated pigments can be used for many polymeric materials, such as PP, PET, PA, PLA, etc.

Use as basic material for making nano-grade mono masterbatches/ SPC with different polymers as carriers.

The original shape and size of nano pigment particles is protected in the chosen polymer.

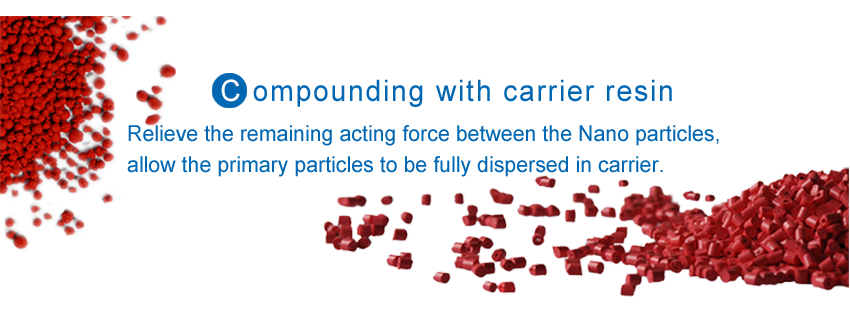

In this process, on the basis that nanoparticles’ surface was coated, through the screw high shear mixing of pigments and polymer, the shear force completes the nanoparticles’ infusion with polymers and enables the nano particles to be uniformly distributed in polymer with their primary shape and size, to finally achieve the purpose of dispersion, and the nano particles can achieve the most stable state in this way, thereby laying the foundation for the manufacture of nano grade custom-made color masterbatches.

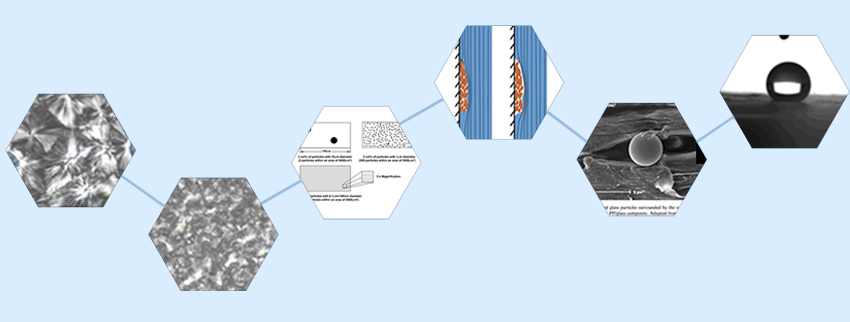

Since the pigment particles in masterbatches which are manufactured by Eisvogel technology are nano-grade, they can confer polymer materials many nano properties, which are specifically performed in following aspects. Taking PP meltblown microfiber processing for example:

○ Enhances the buffer ability of melt materials, effectively buffering the impact of temperature and material index fluctuations.

○ Markedly prolongs the spinneret cleaning cycle by about 50% compared to conventional coloring materials.

○ Significantly reduces melt drops and fiber breakages, potentially improving the stability of fiber production.

○ Achieves approx. 20% increase in fiber strength.

○ Improves the hydrostatic pressure resistance of SMS nonwoven fabrics by approx. 6-25%.

○ Improves material elongation behavior, enabling the ability to spin finer fibers.

○ Reduction in nonwoven defect rates.

○ Ability to decrease nonwoven gram weights while maintaining fabric properties unchanged.

○ Energy savings and reduction in emissions.

○ Lower cost of production for nonwovens.

○ Significantly improved comprehensive performance of nonwoven fabrics, e.g., hydrostatic pressure resistance value, softness, filterability, air permeability, fabric appearance, etc.

○ Enhanced characteristics of the nonwoven product after finishing treatment due to the surface energy of nano materials.

Additional and deeper application results of Eisvogel technology need to be and will be continually explored. We will keep posted on all timely developments.

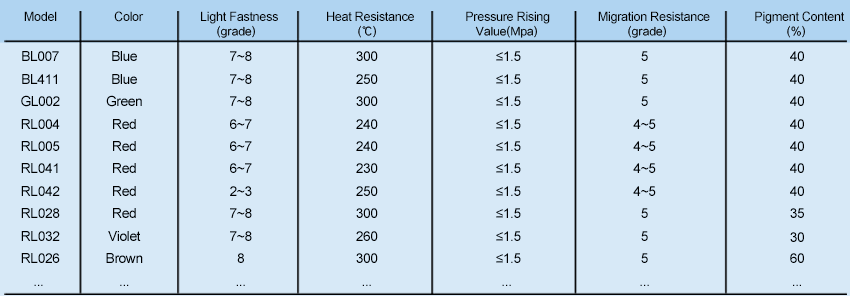

a. Nano-grade mono-color masterbatches/SPC for PP’s coloration

More product information is available for further contact.

b. Nano-grade mono-color masterbatches/SPC for PET and PA is available on request separately.

+86-535-3127700

+86-535-3127700